Brian and Jason both brought in their Titan trucks for a header install and tuning. One problem that plagues all Titans is the factory exhaust manifold cracks. Since the manifold and cat pipe are all one piece there ends up being a tremendous amount of stress on the manifold due to in part by the weight on the manifold and thermal expansion. Up first is Brian who brought in a set of Stillen Headers for his Titan.

Somewhere in that picture is the Stillen Header.

Somewhere in that picture is the Stillen Header.

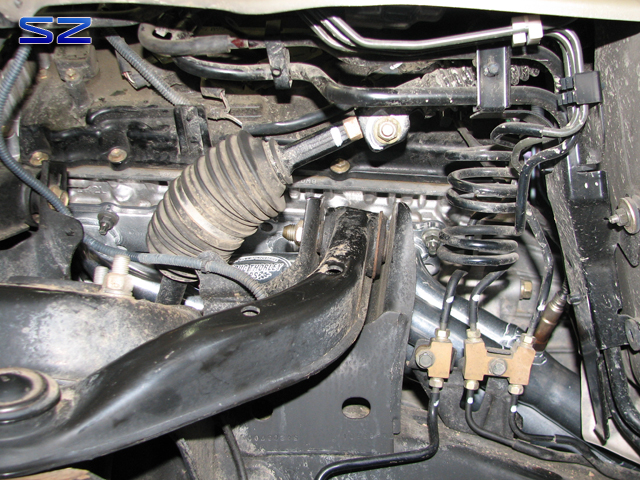

Pic from below of both headers installed. What a joy installing headers on a 4wd truck.

Pic from below of both headers installed. What a joy installing headers on a 4wd truck.

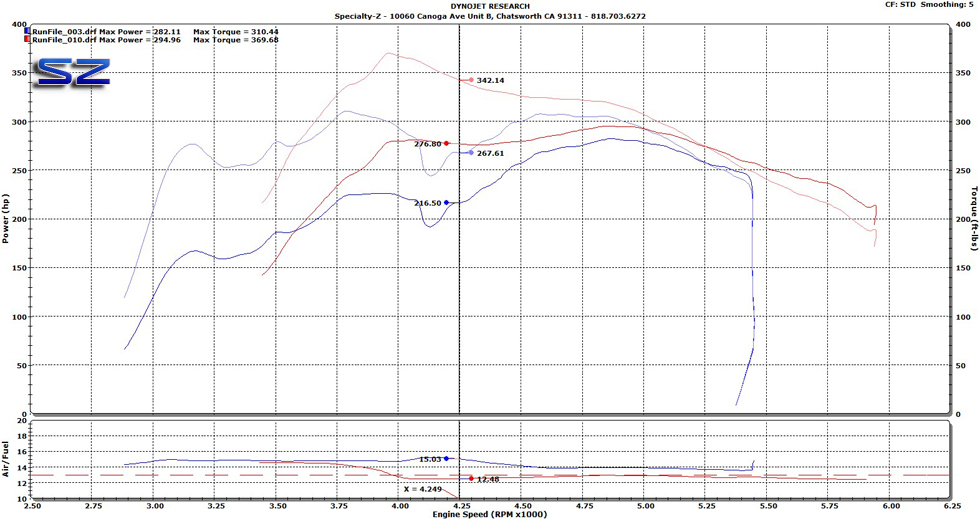

Dynoing the Titan is a tad tricky due to the AT transmission. It wants to downshift as soon as one goes WOT. I had to start above 3800 RPMs. Blue run was after we installed ONLY the headers. No baseline before hand unfortunately. Red run was after we tuned the Titan for some excellent gains. To fully appreciate the headers a tune is a must on these engines\trucks. You can see the AFR on the blue run was bad. Although peak WHP wasn’t crazy the gains throughout the band were huge. Peak torque shot up over 59 wheel torque. You can clearly see the the cursor at 4250 showing some sweet gains. Almost 80 wheel torque gained and 60 whp! Not bad for only headers and tune.

Dynoing the Titan is a tad tricky due to the AT transmission. It wants to downshift as soon as one goes WOT. I had to start above 3800 RPMs. Blue run was after we installed ONLY the headers. No baseline before hand unfortunately. Red run was after we tuned the Titan for some excellent gains. To fully appreciate the headers a tune is a must on these engines\trucks. You can see the AFR on the blue run was bad. Although peak WHP wasn’t crazy the gains throughout the band were huge. Peak torque shot up over 59 wheel torque. You can clearly see the the cursor at 4250 showing some sweet gains. Almost 80 wheel torque gained and 60 whp! Not bad for only headers and tune.

I took a picture of what came off of Jason’s Titan’s manifold. You can easily see the crack. By law or mandate, Nissan and other car manufacturers are responsible for replacing this part since it deals with the cats (emissions components). Sadly though, the dealer will try to pass it off since its a hard job to do (replace manifold) and hard to see it while on the vehicle.

I took a picture of what came off of Jason’s Titan’s manifold. You can easily see the crack. By law or mandate, Nissan and other car manufacturers are responsible for replacing this part since it deals with the cats (emissions components). Sadly though, the dealer will try to pass it off since its a hard job to do (replace manifold) and hard to see it while on the vehicle.

Here you can see how the factory tied the factory manifold (TOP) in with the main cat. One reason they do this is to get the cat hot quicker and keep the cat hotter for cleaner emissions. This however does not help manifold longevity. The new shiny ceramic coated header is from Doug Thorley.

Here you can see how the factory tied the factory manifold (TOP) in with the main cat. One reason they do this is to get the cat hot quicker and keep the cat hotter for cleaner emissions. This however does not help manifold longevity. The new shiny ceramic coated header is from Doug Thorley.

These headers from D.T. had cleaner ports than the Stillen pieces.

These headers from D.T. had cleaner ports than the Stillen pieces.

Where’s Doug? If you take a close look you can see the D.T. plaque on the header. Another nice thing about the D.T. headers was NOT having to extend the O2 sensor wiring like we had to do on the Stillen units. We also installed a set of Berk’s HFC B-Pipes for even less exhaust restriction.

Where’s Doug? If you take a close look you can see the D.T. plaque on the header. Another nice thing about the D.T. headers was NOT having to extend the O2 sensor wiring like we had to do on the Stillen units. We also installed a set of Berk’s HFC B-Pipes for even less exhaust restriction.

Your probably wondering why Jason’s truck baselined ALOT lower than Brians. Brian’s truck was not lifted and had factory sized tires. Jason on the other hand had his Titan lifted and equipped with massive monster truck tires. It took two of us to put his wheels back on. Not only are they heavier but he loses a ton of gearing too. This in turn hurts performance (f-ing duh!). WOT started after 3800+ RPMs so ignore it before then on the graph. Blue run is Jason’s baseline. Red is after we installed the D.T. headers, Berk B-Pipes, and tune. Peak power on Jason’s truck came up nicely. Looking at 5k you can see we gained 40 wheel torque and almost 40 whp. This truck would have easily made over 300+whp with the factory sized tires.

Your probably wondering why Jason’s truck baselined ALOT lower than Brians. Brian’s truck was not lifted and had factory sized tires. Jason on the other hand had his Titan lifted and equipped with massive monster truck tires. It took two of us to put his wheels back on. Not only are they heavier but he loses a ton of gearing too. This in turn hurts performance (f-ing duh!). WOT started after 3800+ RPMs so ignore it before then on the graph. Blue run is Jason’s baseline. Red is after we installed the D.T. headers, Berk B-Pipes, and tune. Peak power on Jason’s truck came up nicely. Looking at 5k you can see we gained 40 wheel torque and almost 40 whp. This truck would have easily made over 300+whp with the factory sized tires.

[…] Brian who brought in a set of Stillen Headers for his Titan. Pictures and details after the jump: A Tale of Two Titans | Specialty-Z __________________ 4×4 Titan The […]

I couldn’t be happier with the work done on my Titan at Specialty Z! These guys are BEASTS when it comes to performance and tuning. Thanks Seb! Where’s my UpRev sticker yo?!

[…] article shows really good gains from Stillen and Doug Thorley headers A Tale of Two Titans | oh ya and uprev of course 2007 KC LE 4×4 SERVO is online now […]

[…] The JBA headers were very nice, but proved to be tough to install due to the flange holes being too small. We had to drill out each hole so we could install the headers onto the factory studs. Surprisingly even after 10k+ miles of forced induction and over 45k miles, the stock exhaust manifolds had survived and not cracked! NA Titans are known to severely crack their manifolds, check a previous post here. […]