J&S first introduced their 1st gen of knock control computers back in 1991. Since then J&S has advanced its knock control listening device with the latest technology while still using the factory Nissan (Bosch) knock sensor.

This unit has the technology to use the factory Nissan knock sensor to control knock per individual cylinder or across all 6 cylinders. Having a dedicated knock “ECU” to listen to certain engine noise (detonation) is an answer to the factory Nissan ECU. The factory’s method for controlling & listening to true knock is very poor and works only below a low RPM range.

The unit has LEDs for each cylinder to display which cylinder’s are getting knock. An optional gauge is available to monitor the amount of knock being retarded. It can retard a maximum of 20 degrees which is adjustable from a max of 10 or 20 degrees. It has a boost retard feature for anyone looking to retard timing as boost rises. This feature isn’t necessary on a Z32 TT, but great for a car that has no means of adjusting timing in its ECU and did not come turbocharged from the factory. Another great feature is the ability to hook up some headphones to listen to knock that can’t be heard otherwise. A sensitivity control also allows one to dial in the perfect amount of sensitivity to noise. Even with good tuning certain conditions may occur that this unit can protect your engine against extreme weather conditions (heat), fuel system failures, constant changing racing conditions, and bad fuel.

We put the system to the test as we were very skeptical of its claims from the manufacturer. We started off by inducing knock on one of our own cars to see if the unit could pick up the knock and also make sure it wasn’t picking up “other” non-knock noises. Its processor for “listening” to knock is designed to pick up the certain frequencies made by knock and detonation. In the end we were very surprised to see how well the unit picked up knock while we listened with our head phones and viewed the knock gauge.

This video shows me inducing knock with running higher boost & timing levels than intended to be safe.

Showing the individual cylinder LEDs for which cylinders are knocking.

In this final video I lowered the timing 2 degrees and boost by 1-2 psi, knock was significantly lower.

Two thumbs up from us. It managed to notify us both visually and audibly, while controlling the knock from getting out of hand.

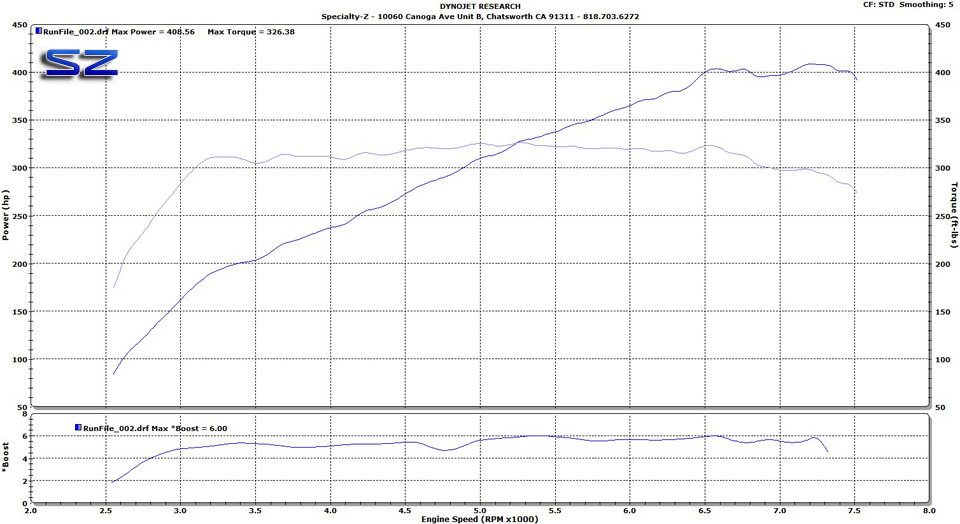

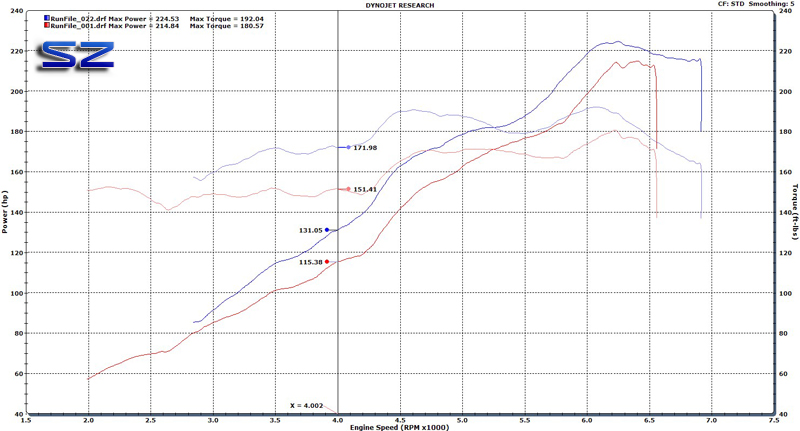

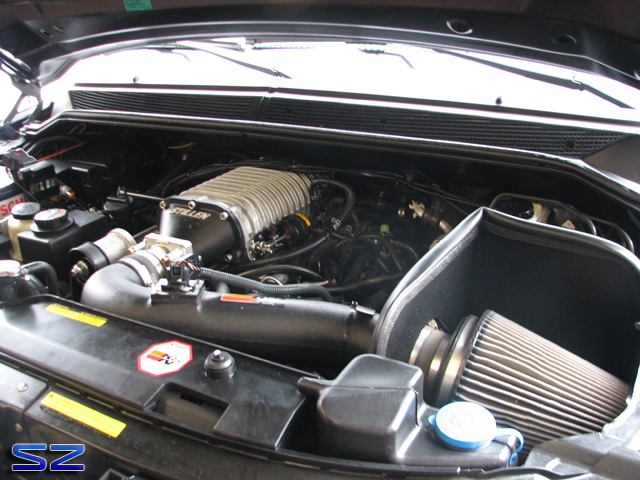

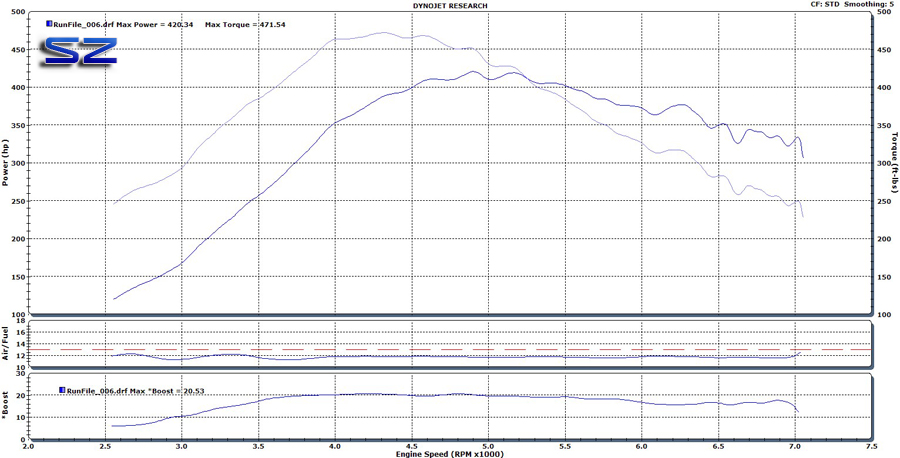

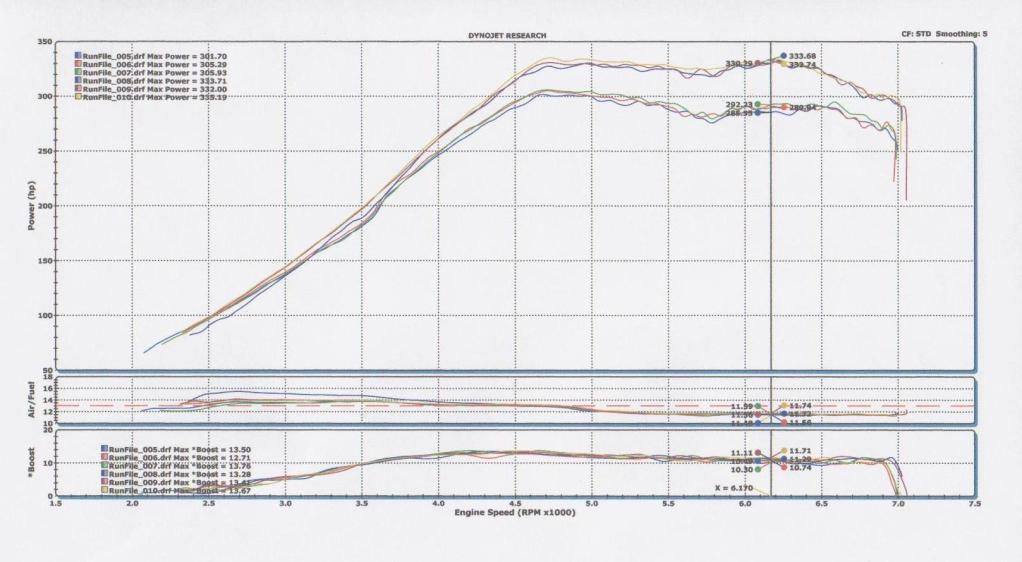

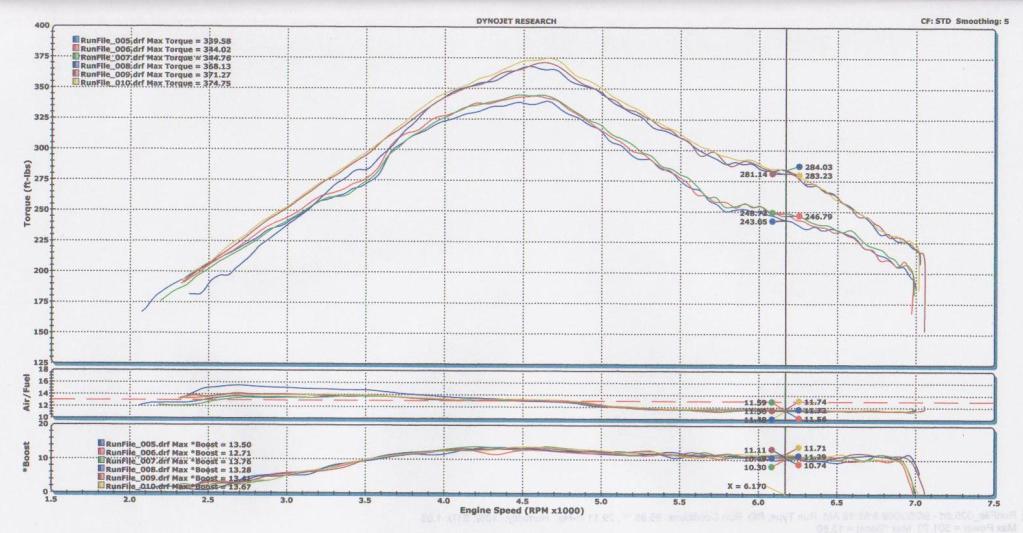

Jesse’s mean looking Z has spent tremendous amount of time at the beauty shop but this Z also packs some heat under the hood. After getting it back from the body shop Jesse brought it over to us to make sure his Z was “healthy” enough for some boost. This Z sports ATI’s Pro-Charger air-cooled centrifugal supercharger. It came to us with a UTEC piggyback EMS and we did a baseline pull to see where it baselined. Z is still running a stock longblock with larger injectors and Walbro pump.

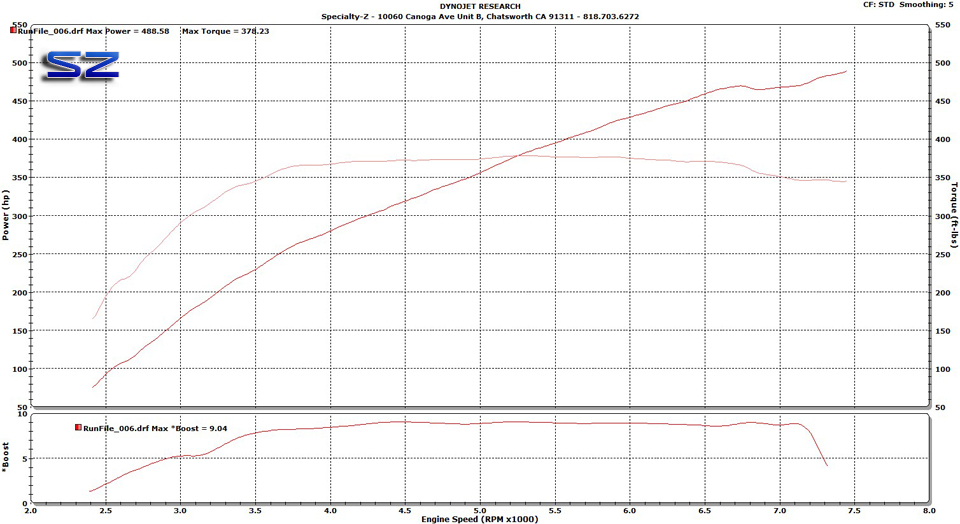

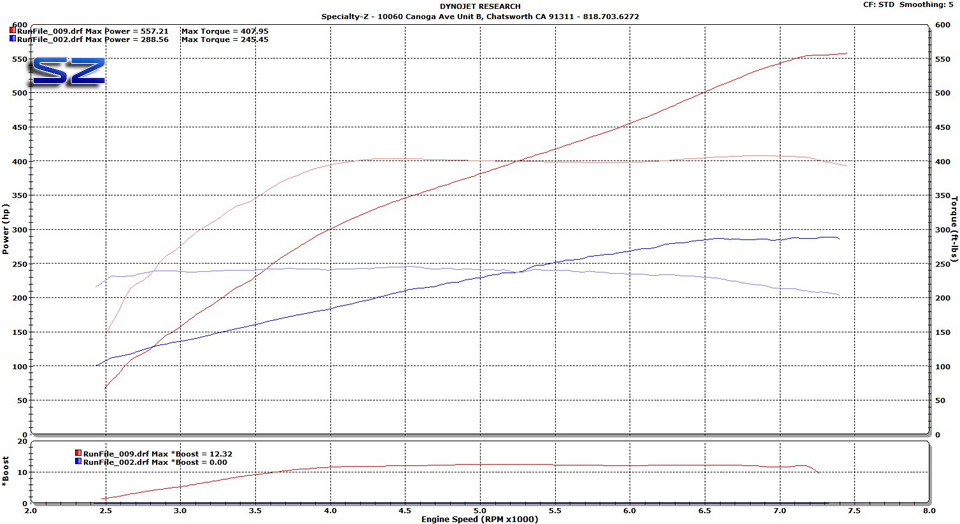

Jesse’s mean looking Z has spent tremendous amount of time at the beauty shop but this Z also packs some heat under the hood. After getting it back from the body shop Jesse brought it over to us to make sure his Z was “healthy” enough for some boost. This Z sports ATI’s Pro-Charger air-cooled centrifugal supercharger. It came to us with a UTEC piggyback EMS and we did a baseline pull to see where it baselined. Z is still running a stock longblock with larger injectors and Walbro pump. You can see his blue baseline run was way too lean the way it came in. We yanked the UTEC out, performed a voodoo ritual & tune up (spark plugs, fluids, etc..), and lovingly tuned this Z. We ended up with a much safer tune and more power & torque throughout the entire powerband (red run).

You can see his blue baseline run was way too lean the way it came in. We yanked the UTEC out, performed a voodoo ritual & tune up (spark plugs, fluids, etc..), and lovingly tuned this Z. We ended up with a much safer tune and more power & torque throughout the entire powerband (red run). Blue was his baseline and red was after some tuning. Even with these basic mods his A\F was very lean to begin with.

Blue was his baseline and red was after some tuning. Even with these basic mods his A\F was very lean to begin with.

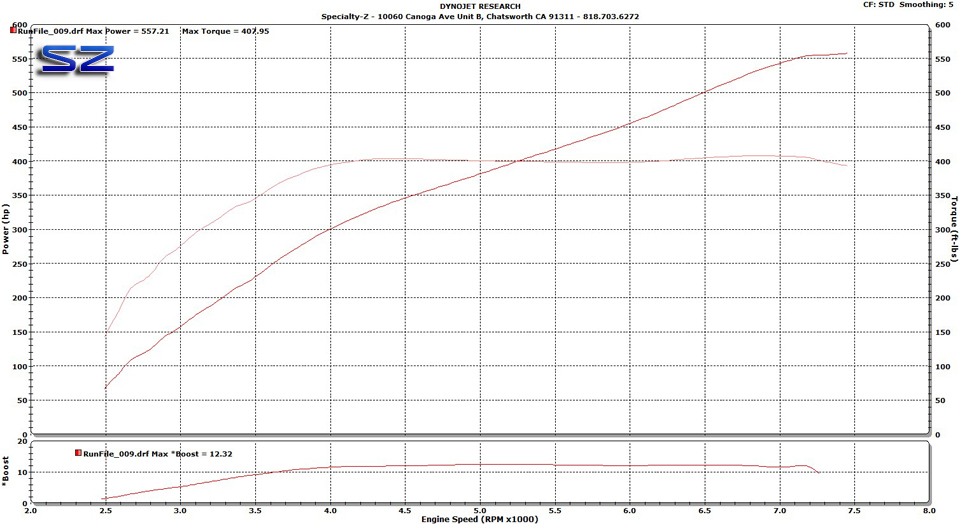

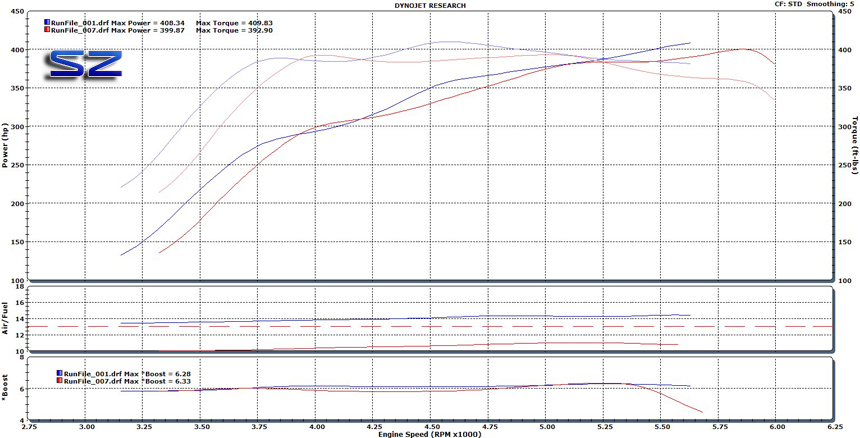

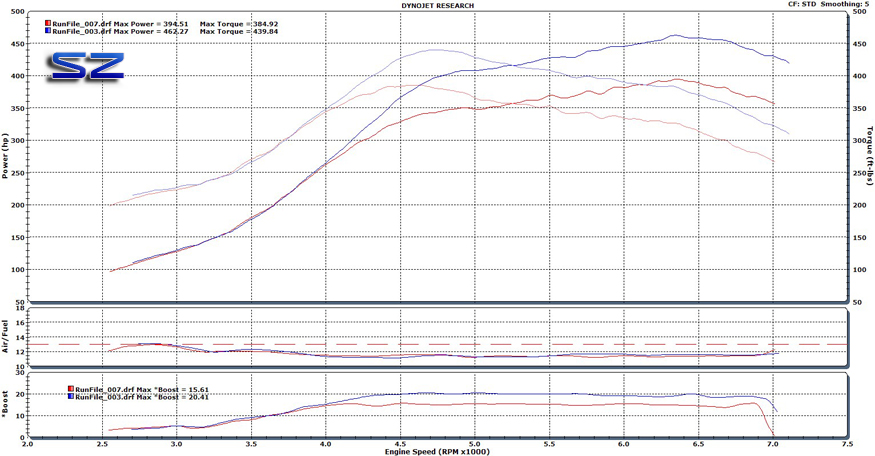

456 whp & 418 torque on 91 Octane. No data gathered on higher octane fuels since the owner has no plans for running higher octane fuel.

456 whp & 418 torque on 91 Octane. No data gathered on higher octane fuels since the owner has no plans for running higher octane fuel.