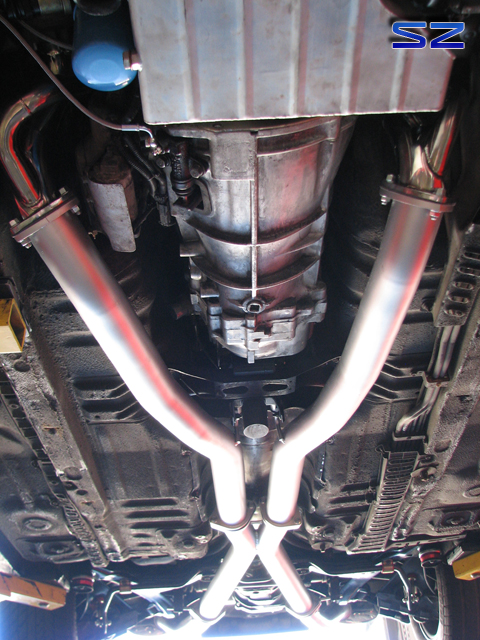

Antonio’s been a customer of ours for almost 10 years. He purchased his Z from our parts manager at Nissan a long time ago. Through the years he did some small upgrades and as its mileage climbed and the fact it was an early 1990 model (valve issues) developed low compression. To add insult to injury, his wife wrecked it slamming into and up a curb. The accident took place sometime around 2003 and he saved the cash to fix it all. His baby was in a real bad place. Antonio was determined to fix the chassis first. The accident took place sometime around 2003 and he saved the cash to fix it all. The frame shop ended up replacing the sub-frame along with a plethora of other things. Once the body was “fixed”, it sat for a few more years before Antonio could save up more cash to dedicate to the engine. Late 2009 came by and it was time to fix his ailing Z. Antonio wanted something that was very reliable and make good power. Nothing too extreme. We sourced a brand new Nissan long-block as the heart and soul. These are now non existent as far as I’m aware. Sport 700s, MSP Manifolds, larger I\C piping, Ash Massives, Z1 T.B.s, full SZ 3″ exhaust, 740cc injectors & 300Degree Rails, Selin Dual POP Kit, SZ Oil Pan, and RPS Twin Billet Carbon Clutch round up the majority of the mods.

To the untrained eye it all looks stock.

To the untrained eye it all looks stock.

After getting the car all back to together and restored we found there were still gremlins plaguing the chassis and driveline. There was still much ado with the suspension. Since the car was hit in the front and rear it ruined the front wheel bearings and also the rear. The RR axle was also damaged and needed replacing. Those have since been replaced. It wasn’t until corner weighted it that we found just how bad everything was. We found that the LR corner was seriously underweight while a majority of the weight was on the LF. Ride height was seriously off. For this we looked to Powertrix and installed a set of their Sport Street Coilovers.

While playing with the front suspension more we also found that the front Stillen anti-swaybar was under extreme pressure. This is not good for handling, ride height and the bar needs to not have any preload on it. Having this off was throwing off the weight and ride height. Not correcting this issue would have us going round in circles. To accomplish this we used high quality SPL End-Links featuring the use of heavy duty 1\2″ bearings.

While one end of the anti-swaybar is tightened down you need to drop the car down on its own weight and attach the other side with no preload. The other side that is already tightened may need adjusting for the “loose” side to attach. Finally with these parts installed we were able to properly corner weight the car to have an almost 50\50 weight distribution (51\49). One more wheel bearing seems to plague this Z so we should have it riding smooth and noise free down the road. With a little more time & money a resto on the exterior will be done.

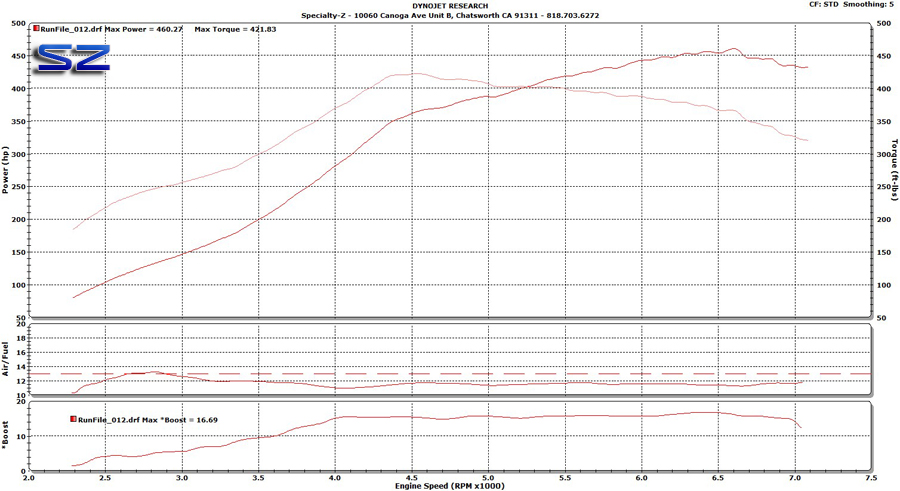

Tuning results after a 1000 mile break in on 91 Octane: